PRODUCTS

CENTER

Dedicated to the research and application of high-performance roller equipment.

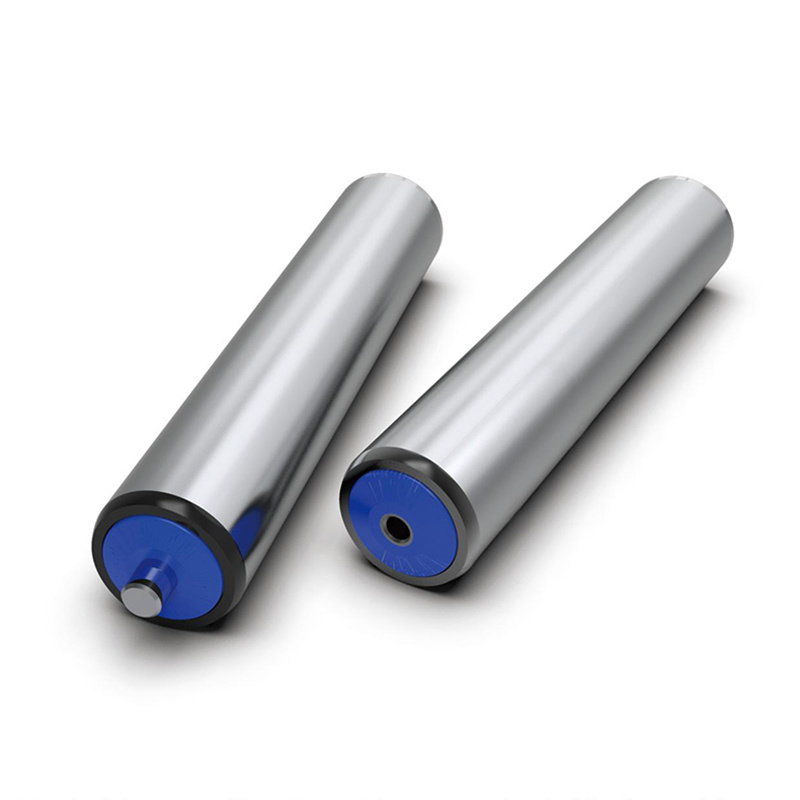

Driven roller

Unpowered transmission is one of the simplest and most widely used transportation methods. The roller is in a passive state, and the goods are transported by gravity or human push and pull, generally arranged in a "horizontal" or "inclined" manner.

"Horizontal": The transportation of goods is achieved by pushing and pulling by human force or other traction methods. This arrangement is suitable for occasions where the weight of the goods is small, the conveying distance is short and the work is not frequent.

"Inclined": The goods rely on the gravity component in the inclined direction to achieve transportation, the greater of tilt Angle and heavier of goods, then the faster the sliding speed.

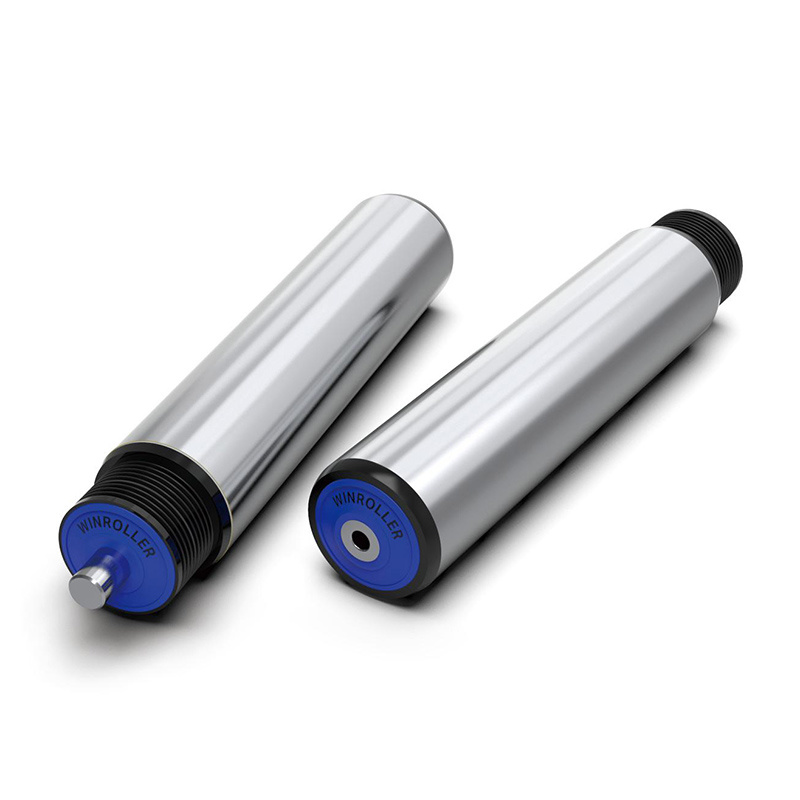

Belt drive roller

Drive transmission can ensure that the goods are accurately, smoothly and reliably transported at the specified speed. The belt drive runs smoothly, little noise, little pollution, and high-speed operation.

However, its load capacity is relatively low, should avoid working in the condition of oil.

Sprocket drive roller

Drive transmission can ensure that the goods are accurately, smoothly and reliably transported at the specified speed. Sprocket drive has a large load and strong adaptability, can be contact with oil, water and high temperature occasions.

However, in a dusty environment, the chain is prone to wear. The speed usually less than 30m/min.

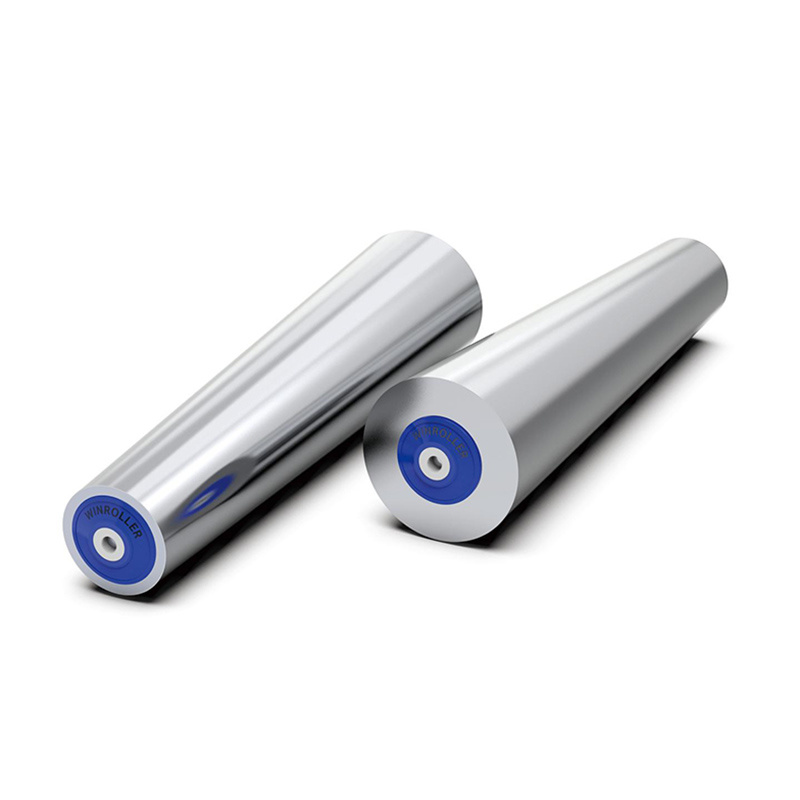

Taper roller

The turning conveyor is realized by the speed difference of the taper face.

Modular PP plastic taper sleeve (250~850mm), beautiful and quiet, fast delivery, low cost, corrosion prevention, easy to clean. The steel tube is durable and can be customized with a standard taper of 3.6°.

Completely anti-static, wide temperature range, suitable for medium load conveying. Standard 3.6° taper (turning radius is about 800mm);

Not anti-static, use at room temperature. The taper roller axis is inclined to 1.8°, and the cone face is kept level.